Customers are Migrating and Adopting new Digital Work Instruction Solutions

The manufacturing landscape continues to evolve rapidly, and the adoption of digital work instruction software has become imperative for companies striving to digitalize tribal knowledge, enhance productivity, streamline processes, and maintain quality. However, many digital work instruction solutions need more capabilities to meet modern workers where they are and support how they learn.

Suppose you’re considering a new digital work instruction solution or migrating from a current solution that fails to meet your expectations. In that case, consider several factors in your search for a better option. Migrating to a new digital solution can be daunting, fraught with challenges ranging from data migration to user adoption, but choosing the right solution should ensure an easy transition for both the content and users.

When our customers share their pains about work instructions and assembly and repair processes, they often discuss the changing workforce, the complexity of different learning styles, and the limitations of current solutions, whether homegrown or software. At CDS, we have the benefit of working with customers, implementing digital work instructions for the first time, and migrating from existing solutions that failed to meet their needs.

We compiled a list of the top five “must-haves” from our customers that ensure a smooth transition and maximize the benefits when selecting a new digital work instructions software:

1.) Seamless Migration Process

Transitioning from an existing solution to a new digital work instructions software should be seamless and minimize disruptions to your operations. One key feature to look for is easy migration capabilities. Whether you’re currently using paper-based instructions, PDFs, or another digital platform, the new software should offer robust migration solutions to facilitate the transfer of existing data quickly and easily.

Advanced solutions leverage artificial intelligence (AI) to automate the migration process, enabling the conversion of PDFs or other file formats into the new system with minimal manual intervention. Leveraging AI not only accelerates the transition but also ensures data integrity and consistency across platforms. Additionally, the software should support customization options, allowing users to map existing workflows and structures to the new platform seamlessly.

2.) Support for 2D and 3D Interactive Work Instructions

Modern workers need more than static text or photo-based work instructions to assemble and repair equipment effectively. Investing in digital work instructions software that supports both 2D and 3D interactive formats will enhance comprehension, improve accuracy, and accelerate task completion for workers of all different learning styles.

Traditional 2D digital work instructions clearly represent sequential steps, making it easier for operators to follow procedures and troubleshoot issues effectively. Utilizing 3D interactive work instructions offers a more immersive experience, allowing users to manipulate virtual models, zoom in on specific components, and simulate assembly processes in real-time.

Combining 2D and 3D elements helps users gain a comprehensive understanding of complex tasks, leading to higher productivity, reduced errors, and enhanced training outcomes. Your digital work instructions software should also feature intuitive navigation controls and customizable viewing options to accommodate various learning styles and preferences.

3.) Easy Updates, Feedback Loops, and Procedure Sign Offs

Continuous improvement is a cornerstone of operational excellence, and the ability to update work instructions in real time is essential for adapting to evolving processes, regulations, and best practices. When evaluating digital work instructions software, prioritize solutions that offer easy updates and feedback loops (including sign-offs) to foster collaboration and iteration.

The best solutions provide intuitive editing tools that enable authorized users to modify instructions, add annotations, or incorporate multimedia elements without extensive training or technical expertise. Additionally, built-in version control mechanisms ensure that users always have access to the latest revisions, minimizing confusion and errors on the shop floor.

Your new solution should facilitate seamless communication and feedback loops between frontline workers, supervisors, and subject matter experts to ensure quality. Integrated commenting features, instant messaging, procedural sign-offs, and collaborative workflows empower users to share insights, report issues, and suggest improvements in real time, fostering a culture of continuous learning and innovation.

4.) Robust Integration with your ETQ Training Management

To maximize efficiency and leverage your existing investments, it is essential to choose digital work instructions software that seamlessly integrates with other systems and tools within your organization’s ecosystem, including your ETQ Training Management system. The powerful integration feature brings seamless collaboration between your digital work instructions and ETQ to provide a unified and streamlined experience for managing training processes.

With a few simple clicks, you should be able to create a connector, publish procedures from your work instructions software to ETQ, and easily track the progress in both.

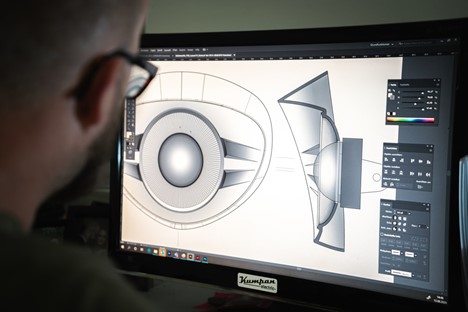

5.) Studio Capabilities for Editing 3D Visualizations

Digital work instructions require the ability to create captivating 3D visualizations that go beyond mere documentation and images for optimal comprehension, engagement, and effectiveness. A comprehensive solution should offer robust studio capabilities that empower users to edit visualizations with animations, colors, textures, materials, finishes, and other graphical elements.

Enhanced studio capabilities for 3D visualization editing are essential features of modern digital work instructions. Empowering users to customize animations, colors, textures, and other graphical elements can improve engagement, optimize workflows, improve learning outcomes, and drive continuous improvement initiatives that fuel long-term success and innovation.

Migrating to a new digital work instructions software represents a significant opportunity for organizations to enhance productivity, quality, and agility in today’s evolving market. By prioritizing features such as seamless migration, support for interactive formats, easy updates, robust integration capabilities, and enhanced studio capabilities, you will ensure a smooth transition and unlock the full potential of digital workflows to drive sustainable growth and innovation.

CDS Mentor is the premiere solution for 2D and 3D digital work instructions. If you are shopping for your first solution or looking to replace a vendor with a future-proof solution, reach out to us and learn how Mentor can support your initiative.